In every operation, you’ll inevitably have to make changes. When you do so, you have many options. Do you toss everything you’ve been using and invest in all new components? Do you reuse what you can and supplement? You’ll look at many factors to decide what to do: cost, timeline, life span, maintenance issues, etc. In this case, replacement chain and attachments were going to be required, but what was the best way for this customer to go about choosing what to do? ErieTec was there to help.

Success Story: Chain and Attachments on Debarker Line

Problem

The customer had decided to revamp an old log deck for one of their debarkers. The deck would now be in a slight incline. Because of this, they were going to have to make changes to the line in order to keep the logs separated and to keep them from rolling down the incline to the debarker infeed. One option would have been to purchase a complete new deck and refit with another chain (requiring sprocket and track changes, too), but the customer wanted to reuse what they could. Additionally, those solutions were expensive and the delivery would take too long for their schedule.

Solution

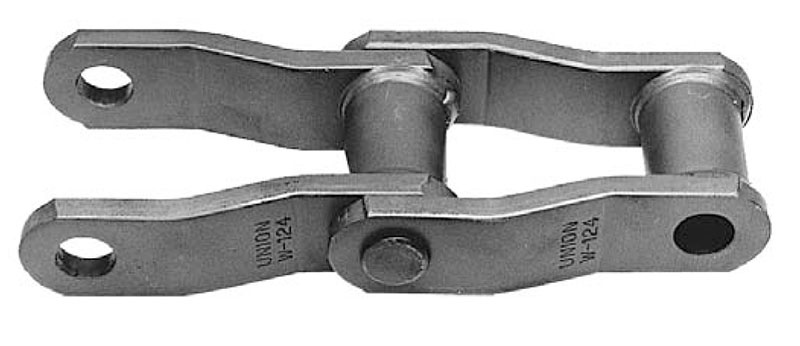

ErieTec proposed a side lift attachment that could be used on their current size chain. While they had wanted to re-use their current chain, we suggested buying the chain complete with the added attachments. This would save time and labor, and they could also use the current chain as a spare for their other flat log deck that wouldn’t require the attachments in order to operate. We also suggested a chain with longer lifespan: the WH82 hardened chain with higher strength ratings. This chain had a delivery date of 203 weeks, which would be in line with their scheduled maintenance.

Savings Calculation

Because of our solution, the customer didn’t have to buy a complete new log deck or do a major redesign with a different chain. Additionally, we were able to keep them on their projected schedule with a quick delivery and we allowed them to reuse their sprockets and deck tracks. Between the product cost avoidance and the downtime avoidance, we saved the customer around $15,000.

The customer saved about $15,000.

Are you making any plans to revamp your lines? Do you have constant breakdowns on your conveying lines or on debarkers? We have experience with all of it. Call us! Let us help you save.