Enclosed Combination

RX2E Enclosed Combination Soft Starter:

The RX2E Enclosed Combination Soft Starter is a rugged, simple to use soft starter with built-in motor protection, providing greater control in starting and stopping of three phase motors.

RX2E Series soft starters comes standard with a circuit breaker, full voltage rated emergency bypass contactor, door mounted Start/Stop push buttons, Local/Off/Remote selector switch and door mounted MX2 keypad.

Enclosed Non Combination

Enclosed Starters ESW and ESWS:

Ready to use Enclosed Full Voltage magnetic starters are the most commonly used devices to switch AC motor loads.

This non-reversing non-combination starter consisting of a contactor and a bimetallic overload relay assembled together inside a NEMA type 1 enclosure.

Two optional pilot devices are available factory-mounted.

Either START / STOP pushbuttons or no-pilot device on the cover are on the shelves ready to go. Field Kit modifications are also available as accessories.

Micro Drive

GA500 Drive:

The GA500 Industrial AC Microdrive is engineered to help you easily handle nearly any application.

Sustainability, flexibility, and ease of use are all designed into the drive, helping you make complicated tasks simple.

Offering intuitive interaction and world-class quality, the GA500 is the drive you can count on for constant, high quality performance.

GA500 Core Features:

- No power programming

- Intuitive keypad

- Conformal coated (IEC 60721-3-3: 3C2, 3S2)

- Up to 30% smaller than the competition

- Current vector control, open loop

- Induction motor (IM), permanent magnet motor (PM), or synchronous reluctance motor operation

Regen Drive

RGX regenerative variable frequency drives:

The RGX series of variable frequency drives is specifically designed to meet regenerative and/or low harmonic needs through the use of an active, bidirectional power converter on the front end of a common DC bus drive.

Eliminate the need for an external resistor or mechanical braking, thus simplifying system design, with the RGX VFD’s dynamic performance and great motor handling. It also delivers superior reliability, reducing total current distortion to 2–3%. The Active Front End design offers energy savings and design compatibility for a wide range of applications.

The RGX VFD impacts a wide range of applications including conveyors, ball mills, extruders, centrifugal pumps, driver winders and a variety of test stands.

Core features of the RGX regenerative VFD:

- Ease of use: Uses the core SPA/SPI drive platform therefore, sharing many of the drive-related characteristics of the component drive including Startup Wizard and built-in applications

- Space-saving design: All-in-one package that includes circuit protection, LCL filtering, and AFE drive in a single enclosure

- Efficiency: Exceptional energy savings is achieved the regenerative braking feature

- Rugged: Reliable control module and operating system as SPX, shared components for inverter and Active Front End for reduced spare parts

- Reliable: Meets IEEE-519 standards by reducing THD 2-3%.

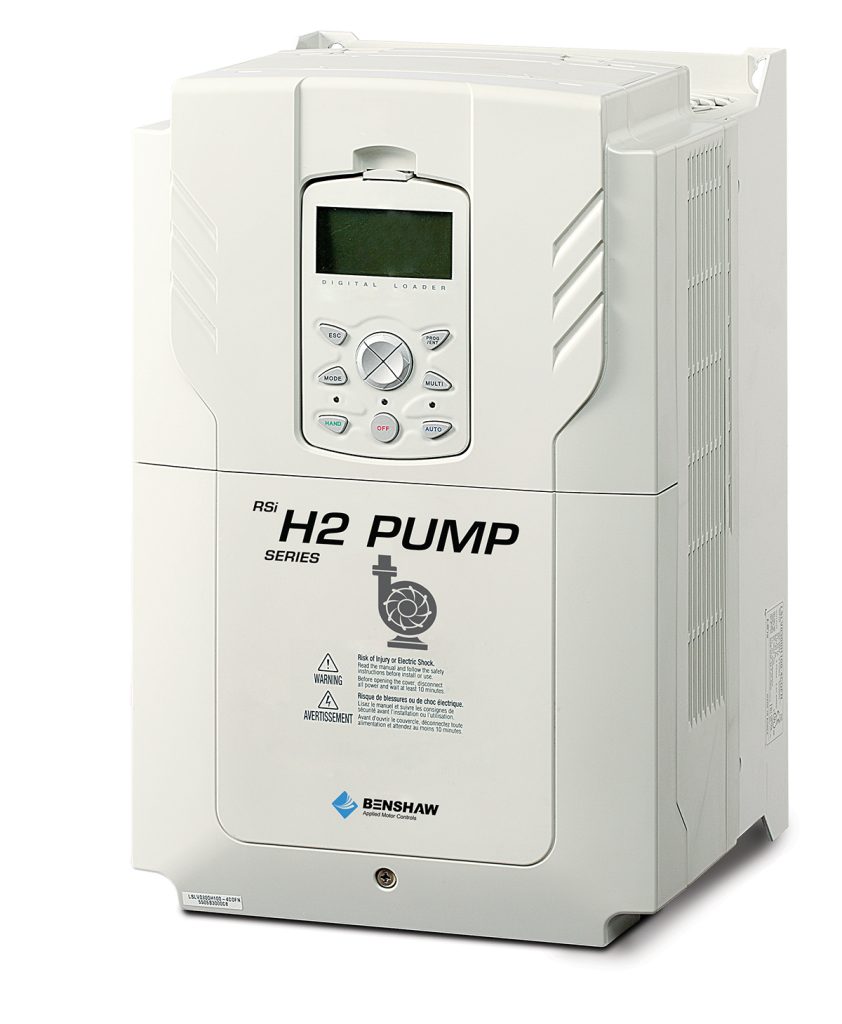

Fan and Pump Drives

H2P Series – Pump/Fan Drive:

The H2P Series sets the new standard for variable frequency drives for pump and

fans applications. It includes application software designed to perform many functions including advanced PID functions, multiple pump or multistage pump control, lead lag, simplex, duplex, triplex, multiplex with the capacity of multiplexing up to 8 drives.

Cost saving result by reducing PLC’s and peripherals typically required to achieve these functions that are now integral to the drive… The results are reduced maintenance cost, better system control, and improved pump and pipe monitoring and protection.

If you have one or multiple motors/pumps in a system that require constant pressure or flow, then this is the drive for you.

Core Features of the H2P Series – Pump/Fan Drive

- The pump is controlled by the unique PID function of AC drive, so external devices such as PLCs or contactors are not required

- The speed of each pump is controlled by individual AC drives to save energy

- Since the operating time of each pump is evenly distributed, the life expectancy of the pumping equipment is extended, reducing the total system operating cost

- If the master AC drive malfunctions, the next AC drive takes over as the master, and continuously controls the system without failure

Full Featured Drives

The A1000 Drive:

The A1000 is a full featured drive, providing outstanding quality, performance, flexibility, and environmental friendliness through 1000HP.

Enjoy network communications, feedback, and expandable I/O to control anything from simple fans and pumps to complex machines.

For new installations or retrofits, the A1000 provides a single robust solution, regardless of your application.

Core Features of The A1000 Drive:

- Closed or open loop vector control for outstanding regulation, torque production, and position control capability.

- Continuous Auto-tuning optimizes performance by compensating for changes in motor temperature.

- High Frequency Injection enables high precision open loop control of Interior Permanent Magnet Motors.

- Fast acting current and voltage limiters help achieve continuous drive operation during periods of excessive demand.

- High Slip Braking reduces installation cost and the need for dynamic braking resistors

Engineered Drives

E7E Drive Engineered:

Custom Engineered Drives required additional engineering time and were supported through custom engineered drawings and documentation.

The E7E provided the features and options for non standard configurations such as 12-Pulse, 18-Pulse, Redundant Drive, etc.

If the standard features and standard options of the E7, E7C, E7L or E7B did not totally fulfill the specification requirements, the Custom Engineered E7E will.

Configured Drives

GA800 Drive:

The GA800 Configured package provides a GA800 in a UL Type 1 or UL Type 12 or UL Type 3R enclosure, with space for several commonly used options, such as reactors, circuit breakers, etc.

The GA800 Configured Package has been designed for flexibility in providing the features and options commonly requested.

This Configured package is designed for tough industrial environments. It is rugged and reliable. A variety of enclosure options provide the right environmental protection.

Core Features of The GA800 Drive:

- High resolution multi-language display with Setup Wizards and Data-Logging.

- Bluetooth (optional) and DriveWizardMobile for convenient and easy interaction.

- Programming without main power through embedded USB port.

- DriveWizard Desktop for comprehensive configuration and monitoring.

A1000 Drive:

The A1000 Configured package provides an A1000 in a NEMA 1 (uL Type 1) or NEMA 12 (uL Type 12) or NEMA 3R (UL Type 3R) enclosure, with space for several commonly used options, such as reactors, RFI filters, circuit breakers, etc.

The A1000 Configured Package has been designed for flexibility in providing the features and options commonly requested.

This Configured package is designed for tough industrial environments. It is rugged and reliable. A variety of enclosure options provide the right environmental protection.

Core Features of The A1000 Drive:

- Closed or open loop vector control for outstanding regulation, torque production, and position control capability.

- Continuous Auto-tuning optimizes performance by compensating for changes in motor temperature.

- High Frequency Injection enables high precision open loop control of Interior Permanent Magnet Motors.

- Fast acting current and voltage limiters help achieve continuous drive operation during periods of excessive demand.

U100 Industrial Configured Drive:

The U1000 Industrial Configured Drive package provides all the low harmonic and regenerative benefits of a U1000 in a UL Type 1 or UL Type 3R enclosure, with space for several commonly used options, such as reactors, circuit breakers, etc.

This configured package is rugged and reliable, specifically designed for tough industrial environments.

Core Features of The U1000 Drive:

- Low input current harmonics

- Facilitate IEEE 519 Compliance

- High efficiency design

- Full regeneration