Hydroduty™

This is the ultimate stainless steel waterproof motor. It has been proven to provide 75% more cycles than other brands through extreme environment testing. Significantly reduces motor replacement and downtime costs. Meets NEMA MG1 Part 31 for Inverter Duty operation; 10:1 CT; 10:1 VT.

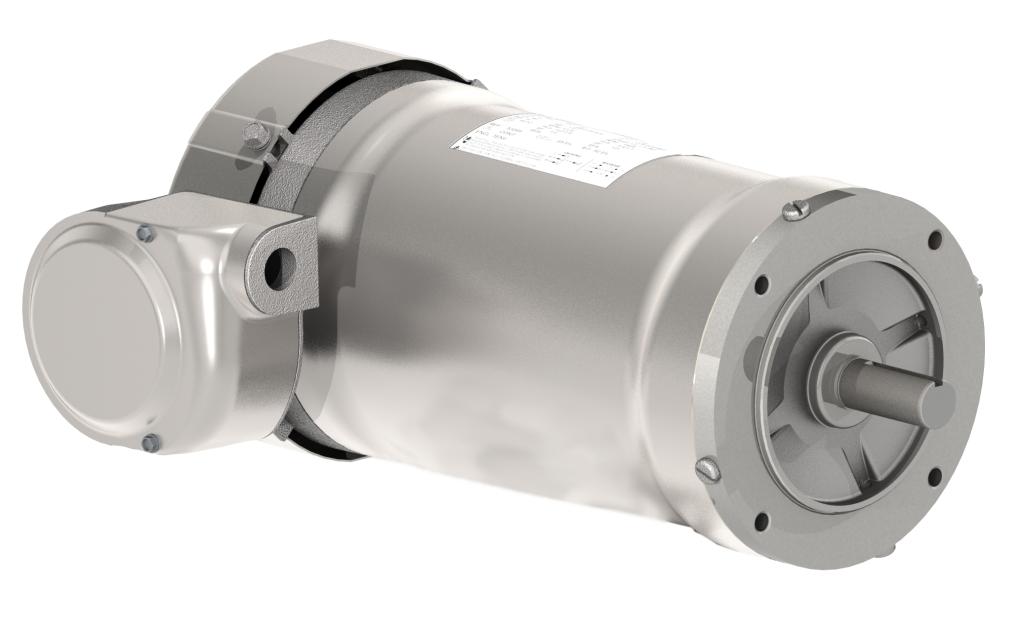

Pickerplus™

Withstands frequent sanitizing with high pressure sprays and caustic fluids Designed to withstand extreme side loading requirements.

Shark™

For use in food processing, pharmaceutical and other applications requiring extreme cleanliness. Class F epoxy insulation. Meets NEMA MG1 Part 31 for Inverter Duty operation; 6:1 CT; 10:1 VT

Hydrowash™

Designed for long service life in general purpose washdown applications. It provides extended service life that can reduce your downtime costs for motor replacement. Meets NEMA MG1 Part 31 for Inverter Duty operation; 6:1 CT; 10:1 VT.

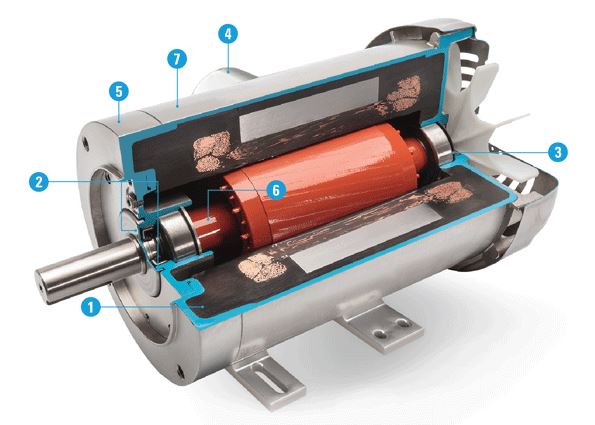

EXTREME DUCK® ULTRA MOTOR

The Extreme Duck Ultra motor stands up to the most demanding high-pressure temperature and dust-penetration environments.

- Fully encapsulated internal epoxy encapsulation – Full body sealing, including both end-bells, reduces air pockets where condensation can occur. Points of entry for contaminants are minimized, and drain plugs and breathers are eliminated.

- Two-piece shaft seal technology- This new design provides three points of protection on both ends of the motor.

- Inner doubled-lipped Viton® shaft seal – this oil, water, and chemical resistant technology are ideally suited for extreme environments that undergo routine washdown.

- Patent-pending 360 ̊ rotatable O-ring smooth-weld sealed conduit box – to simplify installation, the patent-pending smooth-weld conduit box allows for full rotation facilitating wire entry and protects non-wicking, chemical, and abrasion resistant colored leads.

- 300 series stainless steel components – featured on the frame, base, conduit box cover, end-shields and bearing carrier cover. It’s the perfect motor design for extreme washdown conditions.

- Easily removed Q-Car™ rotor cartridge – if bearings need replacement, our exclusive Q-Car™ Rotor cartridge disassembles by removing four bolts saving you time and money.

- Full-fact nameplate – permanently laser etched into the motor frame, this nameplate will never be separated from the motor.

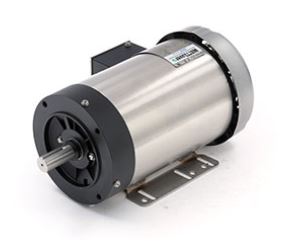

PREMIUM DUCK™ MOTOR

The Premium Duck™ motors are built with all stainless steel external components to prevent corrosion and well-sealed against moisture and condensation to protect internal components. The Washguard® Premium Stainless motors are able to withstand the demanding sanitation requirements found in the chemical processing, pharmaceutical, food and beverage industries.

Single and three phase rigid base, C Face footed & footless, jet pump, brake motors, AC/DC and IEC metric designs are available for applications in severe and frequent washdown environments.

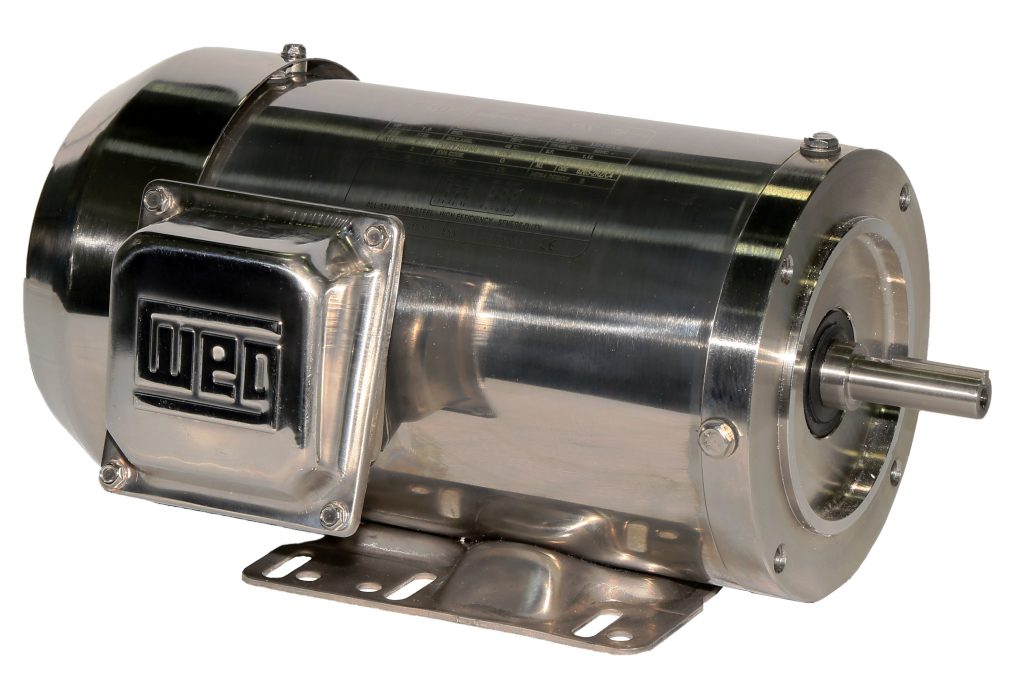

SST DUCK™ MOTOR

The SST Duck™ motors are built with all stainless steel external components to prevent corrosion and well-sealed against moisture and condensation to protect internal components. The Washguard® SST all-stainless steel motors are able to withstand the severe washdown environments found in the food and beverage processing, and chemical processing industries.

Single and three phase, rigid base, C Face footed and footless motors are available for applications in wet or severe washdown environments.

One-year warranty.

Three-year warranty on Premium Efficient designs.

WASHGUARD® II MOTOR

The Washguard® II motors are well suited for the demanding environments of food processing areas requiring frequent sanitation using high pressure cleaning with concentrated caustic solutions, areas of high humidity, and in chemical environments. Typical applications include bakeries and food processing facilities, as well as conveying.

Three phase, paint-free stainless, C Face footed and footless, TEFC, AC motors are available for applications in high humidity or washdown environments.

One-year warranty.

Three-year warranty on Premium Efficient designs.

WHITE DUCK™ MOTOR

The White Duck™ motors are suited for an occasional wash down application in conveying, bottling, food packaging, pumping, and fan applications where batch or process requirements demand reliable performance.

Single and three phase, epoxy coated, rigid base, C Face footed and footless, jet pump, brake motors, and AC/DC gearmotors are available for applications in wet, humid, or washdown environments.

One-year warranty.

Three-year warranty on Premium Efficient designs.