Bucket Elevators

Bucket elevators are one of the most efficient ways of conveying bulk materials vertically and due to the nature of the equipment they typically maintain the integrity of the bulk materials being conveyed.

A Bucket Elevator consists of a series of buckets attached to a belt or chain with pulleys or sprockets located at the top and bottom of the unit. The buckets are located in a casing or housing to contain the material. Bulk materials are loaded into each bucket as the bucket moves past an inlet point.

Bucket Elevators are used in many industries with material including, soaps, ceramics, carbon black, fiberglass, metal powder, fertilizer, grain, sugar, flour, salt and much more.

Through our industry-leading partners, we can help you design and install a wide variety of bucket elevators based on the characteristics of the bulk material and the process requirements.

Advantages of Using Bucket Elevators

- Designed to handle a wide variety of bulk materials

- from average to very free-flowing

- Many different bucket and casing sizes available for capacities up to 15,000 cubic feet per hours

- Inlet section can be control fed or flood loaded with bulk materials

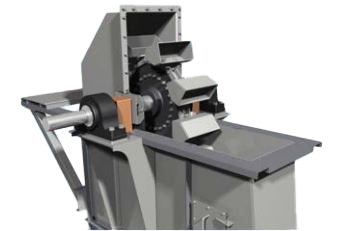

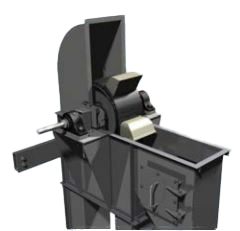

Chain Bucket Elevators

Mill Duty

Offered As:

- Series MDC with AC Buckets mounted on a chain.

- Series MDC with ACS Buckets mounted on a chain.

- Series MDB with AC Buckets mounted on a belt

Series MDB Belt Elevators may have a single or double row of AC Buckets bolted to a heavy-duty rubber covered belt.

Product is centrifugally discharged as material passes over the head Traction Wheel or Pulley.

Belted Bucket Elevator

High Speed Grain

Offered As:

- Series 500 (double leg)

Specifically designed to economically handle grain and other free-flowing materials weighing less than 60 pounds a bushel.

High-Speed Grain (HSG) Elevators may be used in light-duty applications such as grain

Centrifugal Discharge

Offered As:

- Series 100 (boot Take-Up)

- Series 200 (head Take-Up)

Available with buckets mounted to a chain or belt

Handles free-flowing materials with small to medium lump size

Discharges the material by centrifugal force

Continuous Discharge

Offered As:

- Series 700 (boot Take-Up)

- Series 800 (head Take-Up_

Available with buckets mounted to a chain or belt

Handles bulk materials ranging from light to heavy and from fines to larger lumps

Buckets are loaded by direct feeding with the use of a loading leg

Spillage of materials is minimized by the close bucket spacing

As buckets discharge, material flows over the preceding buckets; projecting sides for a chute, assisting in proper discharge